Fibroin is a fibrous protein that constitutes the main component of silk produced by the silkworm (Bombyx mori), representing approximately 70-80% of the total composition of the silk thread. From a structural perspective, B. mori fibroin is characterized by a macromolecule composed of a heavy chain (H-chain) of about 350 kDa and a light chain (L-chain) of 26 kDa, linked by an intermolecular disulfide bridge. The heavy chain features a highly repetitive amino acid sequence with crystalline domains primarily consisting of hexapeptide sequences of the type (Gly-Ala-Gly-Ala-Gly-Ser)n. These domains alternate with more hydrophilic and structurally less organized amorphous regions, rich in amino acids with bulkier side chains such as tyrosine, valine, and aspartic acid. The predominant secondary structure in the crystalline regions is the antiparallel β-sheet type, with polypeptide chains organized in stacked β-sheets that confer fibroin its characteristic mechanical properties of tensile strength and rigidity.

Structural integrity

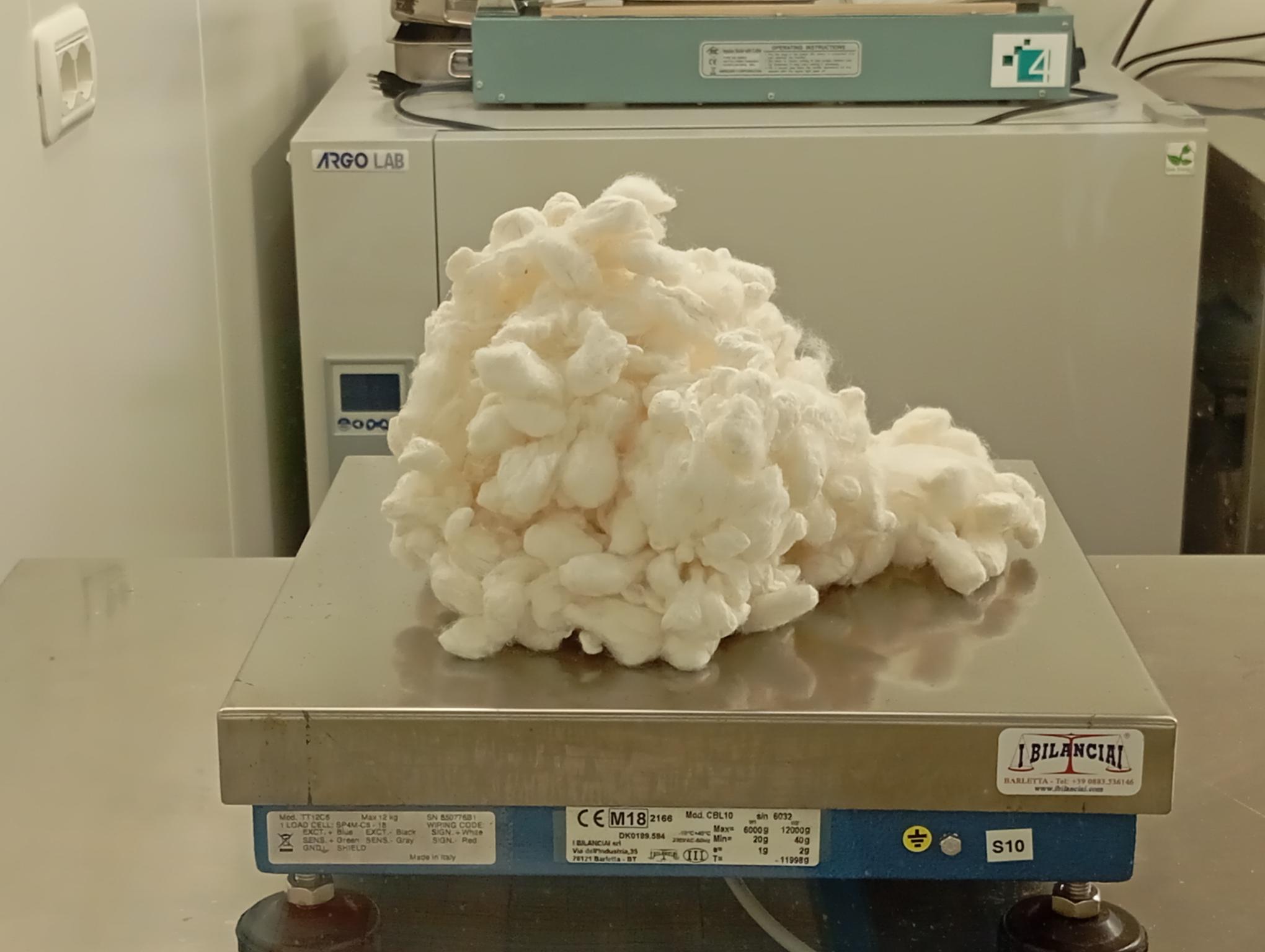

The process of extracting fibroin from silkworm cocoons requires sophisticated biochemical protocols to preserve its structural and functional integrity. The standard methodology involves a preliminary degumming phase by boiling in an alkaline solution of Na?CO? (0.02-0.5% w/v) to remove sericin, a hydrophilic glycoprotein that coats the fibroin fibers. Subsequently, the purified fibroin is solubilized in concentrated chaotropic solutions such as lithium bromide (LiBr 9.3M) or mixtures of calcium chloride, ethanol, and water (CaCl?/C?H?OH/H?O in a molar ratio of 1:2:8). The critical step is represented by extensive dialysis against deionized water, which induces a conformational transition from random coil to β-sheet structures, controllable through parameters such as pH, ionic strength, and temperature. Conformational analysis by FTIR spectroscopy reveals characteristic bands at 1620-1630 cm?¹ (amide I) and 1510-1520 cm?¹ (amide II) indicative of the β-sheet structure, while X-ray diffractometry shows reflections at d=4.5Å and d=10Å corresponding respectively to the distance between stacked β-sheets and the periodicity along the polypeptide chain.

Cellular sequences

Extracted fibroin possesses extraordinary physicochemical and biological properties that justify the growing interest in advanced biomedical applications. The presence of alternating hydrophobic and hydrophilic domains confers the protein an amphiphilic behavior that facilitates its processability into various morphologies such as films, porous scaffolds, hydrogels, microspheres, and nanofibers through techniques including electrospinning, lyophilization, phase separation, and self-assembly. At the cellular level, fibroin demonstrates excellent biocompatibility derived from the presence of cryptic RGD (Arg-Gly-Asp) sequences that, when exposed during processing, promote cell adhesion through specific integrins. Proteomic studies have shown that fibroin can modulate the expression of over 200 proteins involved in mechanotransduction, cytoskeleton regulation, and cell cycle progression. The enzymatic degradation of fibroin in vivo occurs mainly through the action of proteases such as chymotrypsin and protease XIV, with kinetics controllable through the degree of crystallinity of the protein: highly crystalline structures with high β-sheet content show degradation times on the order of 6-12 months, while more amorphous conformations are metabolized in 2-4 weeks.

Technologies and future visions

The most recent molecular engineering techniques have allowed for genetic modification of fibroin by introducing specific functional domains through recombinant DNA technologies. Using heterologous expression systems in Escherichia coli or mammalian cells, it is possible to produce chimeric fibroins incorporated with bioactive sequences such as binding domains for growth factors (TGF-β, BMP-2), antimicrobial peptides (magainin, defensin), or immunomodulatory epitopes (IKVAV, YIGSR). Nanostructural characterization using atomic force microscopy (AFM) and transmission electron microscopy (TEM) has revealed that the folding and supramolecular assembly of these recombinant fibroins follows concentration-dependent non-linear kinetics, with formation of metastable intermediate structures characterized by spherical domains of 20-50 nm that progressively aggregate into fibrils with diameters between 10-30 nm and micrometric length. Rheological analyses demonstrate that fibroin solutions exhibit non-Newtonian viscoelastic behavior with pronounced shear-thinning at concentrations above 2% w/v, and a thermosensitive sol-gel transition in the range of 37-45°C correlated with the formation of intermolecular hydrogen bonds and hydrophobic interactions that stabilize the three-dimensional protein network.